Video: Ergonomics and Economics of Really Big Laser Powder Bed Fusion

The DMP Factory 500 solution currently operating at CIMP-3D offers a look at the equipment and steps necessary to 3D print metal parts at large scale.

Share

As laser powder bed fusion (LPBF) machines get larger, they introduce new challenges when it comes to the ergonomics and economics of 3D printing metal parts from powder. Scaling up means adopting more equipment into the AM workflow for safe handling of parts, build plates and materials; simultaneously, the value of machine time and cost of parts can shift. This video filmed at CIMP-3D, the Center for Innovative Materials Processing through Direct Digital Deposition located at Penn State University, looks at a large-format “factory” built around a 3D Systems DMP500 3D printer with a build area measuring 500 × 500 mm.

To deal with the heavy build plates, large amounts of powder and big parts produced, this machine is surrounded by a collection of peripherals. This equipment includes a Build Breakout Station, Powder Recycling Module, specialized wire EDM, and a transportation module to move material and builds ergonomically. While this machine can be applied to make very large parts, its more economical application might be to produce multiple smaller parts at once.

Transcript

Laser powder bed fusion is getting larger, but working with a large format 3D printer requires some unique considerations with regards to ergonomics and economics.

I'm Stephanie Hendrixson here at CIMP3D. This is Penn State's Center for Innovative Materials Processing through Direct Digital Deposition. One of the pieces of equipment that they use here is this DMP 500 from 3D Systems.

This is a large format 3D printer with a build plate that measures 500 by 500 millimeters.

can make really large parts in builds that take hours up to days. But to really make use of this system required a whole suite of auxiliary equipment. Basically, you have to build a large-format factory around this printer.

In the case of this DMP 500, the core of the whole system is the Removable Powder Module, the RPM. This is a removable unit that contains the build plate and all of the material needed for a given print. Before the build starts, the RPM is installed into the printer. It has to be moved using a transportation module that has been specifically designed by 3D systems for use with this machine.

Once the build is complete, the entire RPM is removed to the Build Breakout station. There are glove boxes on either side of this unit that allow two different operators to be depowdering at the same time. There's also an arm inside that can lift the build plate, tilt it and vibrate it to get all of the excess material out.

From there the RPM with all of that excess material is going to the Powder Recycling Module. That's where the material is going to be filtered and prepared for reuse.

Meanwhile, the build plate with all of the parts is going to this wire EDM that was developed by GF in collaboration with 3D Systems, specifically for 3D printed part cut-off.

So you need all of these different peripherals in order to make this system work because of the ergonomics. It would just be difficult to deal with parts and build plates and equipment of this scale. The build plates alone can be so heavy that you need two operators to move them, if you want to move them that way at all. You're dealing with a lot of powder, maybe 200 kilograms or more per build, and the parts that are made in this machine tend to be heavy and awkward to manage. And so all of these additional pieces of automation and ergonomic equipment are necessary for this to work.

So where does a large format, large frame printer like this make sense? The obvious answer is for making really big parts, especially when you're thinking about things like casting replacements. But there are also other reasons to choose a large format 3D printer. If you think about it, the build plate inside of this machine could potentially take the place of four smaller build plates that would be found inside of a smaller mid-frame machine, and so you might be able to print four or more parts all at once that would take multiple pieces of equipment otherwise. So you're getting the same number of parts in the same amount of time just with one machine, so it could be the more economical choice as well.

Related Content

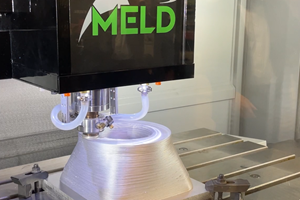

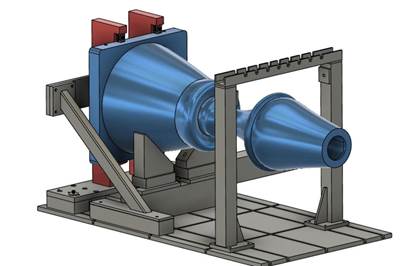

3D Printing From Barstock Using Friction Stir Welding (Video)

A look at the Meld Manufacturing metal AM process. The machine tool in this video builds an additively manufactured part by rotating and compressing metal bar.

Read MoreLarge-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

Read MoreHow Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read MoreRobot Deposition Makes Giant Industrial Mixer Blade: The Cool Parts Show Bonus

Wire arc additive manufacturing produces a large component formerly made through casting, and allows for redesign of its internal cooling geometry.

Read MoreRead Next

How to Organize for Additive Production: AM Radio #42

Tim Simpson and Peter Zelinski discuss the next steps for succeeding with AM: After technical and process successes come the cultural, organizational and even costing considerations associated with this mode of manufacturing.

Read MorePart Removal Efficiency In a 600 mm Plus World

Clay Olson of EDM Performance Accessories discusses the difficulties and opportunities in cutting off parts from the build plates of large AM systems. Molybdenum wire EDM offers an effective solution to the challenge of large-part cutoff.

Read MoreGE Additive Rebrands as Colibrium Additive

As part of the brand name transition, both the Concept Laser and Arcam EBM legacy brands will be retired.

Read More

.jpg;width=70;height=70;mode=crop)